By the Engineering Team at Butler Technologies, Inc.

The era of the “dumb” medical device is ending. Whether it is a smart garment monitoring an athlete’s recovery or a hospital bed tracking patient movement, the demand for data is driving a revolution in hardware.

At the heart of this revolution are Biometric Sensors.

But for product designers and engineers, the challenge isn’t just knowing what to measure—it’s knowing how to measure it without making the device bulky, uncomfortable, or expensive.

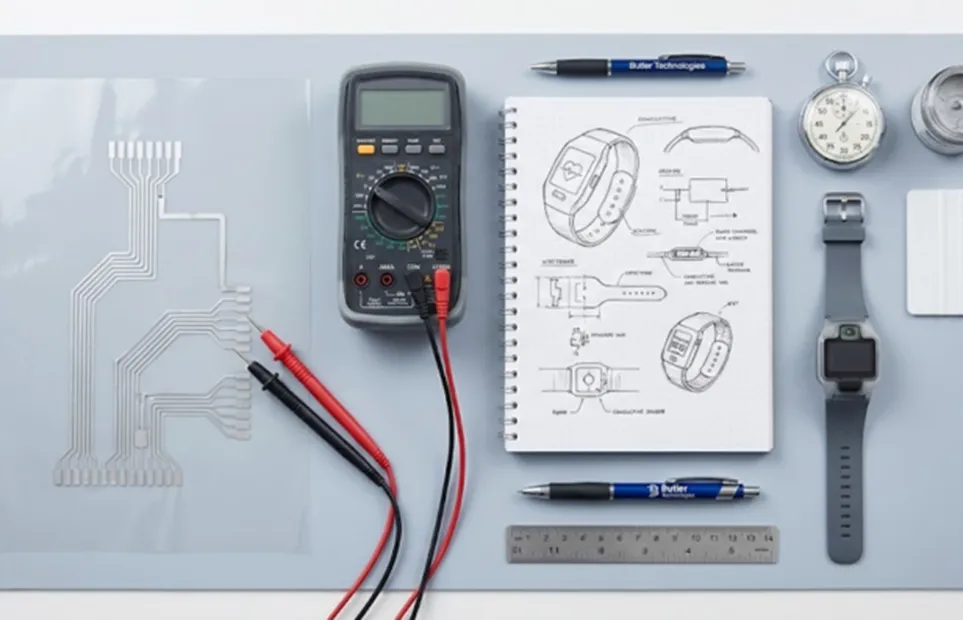

This is where Printed Electronics has changed the game. By moving away from rigid hardware to conductive inks printed on flexible films (like TPU or polyester), we can now integrate these sensors directly into textiles and thin interfaces.

Here is a breakdown of the primary types of biometric sensors we engineer at Butler Technologies, and how they function in the modern wearable landscape.

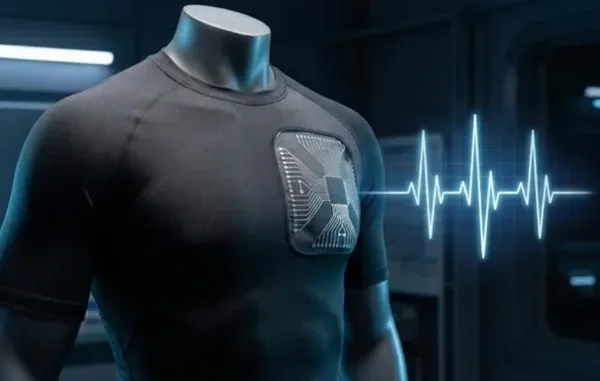

1. ECG / EKG (Electrocardiogram) Sensors

What it measures: The electrical activity of the heart.

How it works: Every time your heart beats, it generates a tiny electrical depolarization. An ECG sensor captures this signal through electrodes placed on the skin.

The Printed Advantage: Traditional ECGs rely on “wet” electrodes (sticky gel pads) and dangling wires. At BTI, we utilize Printed Dry Electrodes. We screen print conductive silver and carbon inks directly onto flexible TPU films.

- Application: These can be heat-transferred into “Smart Shirts” or chest straps, allowing for continuous, comfortable heart rate monitoring without skin irritation or wires.

2. EMG (Electromyogram) Sensors

What it measures: Muscle response and electrical activity.

How it works: When a nerve stimulates a muscle, it creates an electrical potential. EMG sensors detect this to tell you when a muscle is firing and how hard it is working.

The Printed Advantage: EMG is critical for physical therapy and elite athletics. However, rigid sensors are uncomfortable during movement. By printing stretchable silver inks, we create “Smart Skin” patches that stretch with the athlete’s bicep or quad, providing data on muscle fatigue and recovery without hindering performance.

3. FSR (Force Sensing Resistors) / Pressure Mapping

What it measures: Applied force, weight distribution, and pressure points.

How it works: An FSR is a material that changes its electrical resistance when compressed. The harder you press, the more conductive it becomes.

The Printed Advantage: This is one of the most versatile applications of printed electronics. Because we can print FSRs as thin sheets, they can be laminated into invisible areas.

- Medical Application: Smart shoe insoles that analyze gait, or precise fluid management systems that demonstrate how force sensing resistors improve accuracy in infusion pump delivery.

- Industrial Application: Hospital beds that alert nurses if a patient is trying to get up or if they have been in one position too long (pressure ulcer prevention).

4. Temperature Sensors (Printed RTDs)

What it measures: Body heat or skin surface temperature.

How it works: We utilize Resistance Temperature Detectors (RTDs). As the temperature changes, the resistance of the printed circuit changes in a predictable, linear way.

The Printed Advantage: Standard thermocouples are bulky probes. Printed temperature sensors are paper-thin. They can be integrated into a wound dressing to monitor for infection (heat spikes) or into baby monitoring bands to track fever continuously and wirelessly.

5. EDA / GSR (Electrodermal Activity)

What it measures: Skin conductance (sweat levels), often used as a proxy for stress or emotional arousal.

How it works: Your sweat glands are controlled by the sympathetic nervous system. Even microscopic amounts of sweat change the conductivity of your skin. EDA sensors measure this variance.

The Printed Advantage: Commonly used in wristbands and research devices, printed EDA electrodes offer a non-intrusive way to track stress response in real-time, useful for mental health monitoring or high-stress industrial environments.

6. EEG (Electroencephalogram) Sensors

What it measures: Electrical activity in the brain.

How it works: EEG tracks voltage fluctuations resulting from ionic current within the neurons of the brain.

The Printed Advantage: Traditional EEGs look like swimming caps full of wires. While still a developing frontier for printed electronics, flexible circuits are allowing for the creation of low-profile “sleep headbands” that monitor sleep quality without the hard plastic nodes digging into the user’s skull.

Why “Printed” is the Future of Biometrics

Knowing which sensor you need is only half the battle. The harder challenge is integration.

How do you take a sensitive ECG circuit and make it survive a washing machine? How do you place a pressure sensor in a shoe so it doesn’t crack under 200lbs of force?

This is where the engineering reality sets in.

At Butler Technologies, we don’t just print circuits; we solve the “Form Factor” problem. We bridge the gap between rigid electronic components and the soft, curved, dynamic nature of the human body.

If you are ready to move your design from a rigid concept to a flexible reality, start your engineering consultation with BTI today. Whether you need to rapidly test conductive inks on different substrates or ensure your biometric design is ready for mass production, our team is ready to help you scale.

Stop struggling with rigid hardware. Let’s build a device that truly fits the user.

Leave a Reply