If you’re like most people, you probably don’t think twice about the metal objects you use every day—your car parts, kitchen appliances, tools, electronics, and even the fixtures in your home. These items feel so ordinary that it’s easy to forget the incredible engineering and manufacturing processes that bring them to life. Yet behind every smooth hinge, durable handle, or precisely shaped component lies a world of innovation that makes modern living possible.

Today, we’re taking a people-first, easy-to-understand look at the hidden technology behind everyday metal products. Whether you’re a curious consumer, a DIY enthusiast, or someone who loves learning how things work, this article will give you a deeper appreciation for the science and craftsmanship embedded in the objects around you.

Why Metal Manufacturing Technology Matters

Metal has shaped human progress for thousands of years, but today’s metal products are far more advanced than the simple tools of the past. Modern manufacturing relies on high-precision techniques that allow engineers to create parts that are lightweight, strong, efficient, and reliable.

This technology matters because it affects:

- Safety — Stronger metal parts make our cars, appliances, and tools safer.

- Durability — High-quality components last longer and require fewer repairs.

- Efficiency — Technological processes allow for lighter designs that conserve energy.

- Affordability — Advances in production keep everyday products accessible and cost-effective.

- Innovation — New metal-forming technologies enable better gadgets, machinery, and transportation.

Behind these benefits are several lesser-known manufacturing processes that shape the world around us.

The Role of Precision in Metal Products

Think about how precisely a metal zipper snaps shut, how smoothly a faucet turns, or how reliably your car’s engine parts function. None of this is accidental. Precision is essential in metal manufacturing because even the smallest variation can affect performance.

To achieve this level of accuracy, manufacturers rely on advanced technologies that control every detail of a metal product’s shape, size, and strength. Here are some of the most important—yet often overlooked—methods.

1. Casting: Creating Complex Shapes with Ease

Casting is one of the oldest metalworking methods, but modern casting is anything but simple. In this process, molten metal is poured into a mold and allowed to harden. This forms the basic shape of an object—anything from a handle to a gear.

While casting may sound straightforward, modern casting technology allows manufacturers to create extremely detailed and complex shapes. In fact, one method, known as investment casting, is used for producing high-precision parts in industries like aerospace, automotive, and medical equipment. This process allows for smooth finishes, intricate details, and reliable durability.

You’ll find cast metal parts in everyday products such as doorknobs, cookware, hand tools, and even the metal frames of household appliances.

2. Forging: Strength Through Pressure

Forging is the process of shaping metal using compressive force. You can picture this as a modern version of a blacksmith hammering metal—except today’s forging uses massive machines and controlled heating to form extremely strong components.

Forged parts are known for their durability and toughness. That’s why forging is commonly used for items like:

- Wrenches and hand tools

- Automotive crankshafts

- Structural parts in construction

- Bicycle components

- High-strength fasteners

If something must withstand heavy loads or frequent use, forging is often the process behind it.

3. Stamping: The Backbone of Mass Production

Metal stamping is an essential technology for producing large quantities of parts quickly. In this method, machines press or cut flat sheets of metal into specific shapes—similar to how cookie cutters work, but on an industrial level.

Stamping is responsible for many everyday objects, including:

- Car body panels

- Silverware

- Electronics housings

- HVAC components

- Metal clips and brackets

Stamping makes manufacturing efficient and keeps costs reasonable.

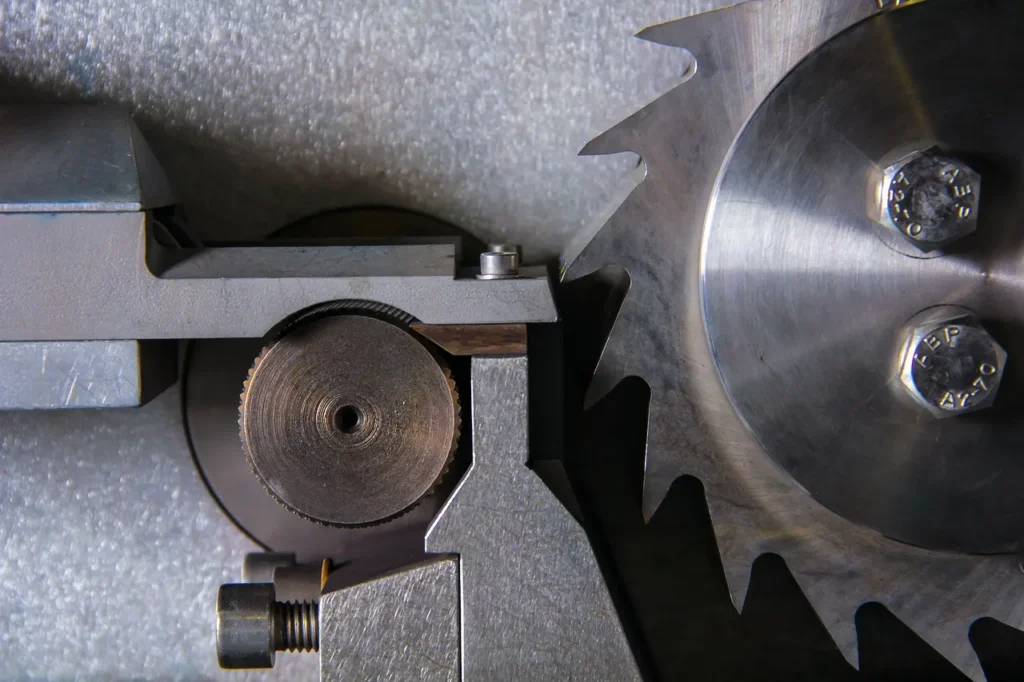

4. Machining: Precision at Its Finest

Machining is often used when a metal part requires exact dimensions or detailed features. Tools like drills, lathes, and milling machines cut or shape metal into highly precise forms.

Common examples of machined products include:

- Bolts and screws

- Medical devices

- Engine components

- Custom hardware

- Electronics connectors

Machining is often the final step in preparing a product for assembly.

5. Welding: Joining Metal with Strength

Welding binds metal pieces together by heating them until they fuse. This process is essential for creating everything from furniture frames to car bodies.

Different welding techniques—such as MIG, TIG, or laser welding—are used depending on the material and design. Everyday items that rely on welding include:

- Fences and gates

- Grills and outdoor furniture

- Bike frames

- Automotive frames

- Appliances and metal structures

Welding ensures metal products stay sturdy and secure for years.

6. Surface Finishing: Strength, Protection, and Style

A metal product’s appearance, texture, and resistance to rust often depend on its finishing process. Techniques like polishing, powder coating, anodizing, or plating help enhance durability and aesthetics.

Surface finishing is used on:

- Door hardware

- Kitchen utensils

- Decorative fixtures

- Car wheels

- Outdoor metal furniture

It’s the reason many metal objects look sleek, resist corrosion, and hold up to everyday use.

Technology Enables Better Everyday Living

From casting and machining to forging and finishing, the technologies behind metal manufacturing keep evolving. These advancements help:

- Reduce material waste

- Improve precision and safety

- Lower production costs

- Support innovation in consumer products

The result? Everyday items that are smarter, stronger, and more reliable.

Final Takeaway

The metal products we rely on each day may seem simple, but they are anything but. Behind every hinge, tool, appliance part, and automotive component is a combination of advanced technology, careful engineering, and skilled craftsmanship. Understanding these hidden processes not only deepens our appreciation for the objects around us—it highlights how innovation quietly shapes our daily lives.

Leave a Reply