Inventory management is an issue for a lot of businesses. There can be an excess of stock sitting in warehouses or a shortage right when customers want the product. Most of the time, this problem occurs because businesses cannot predict exactly how much of something customers are going to buy. Changes, like sales history, seasonal changes, promotional events, market trends, etc., all increase the likelihood of inaccurate planning for the right amount of inventory.

That’s why using the best tools available can reduce that error. A replenishment optimization software backed by a level of intelligence can monitor this activity, improve demand forecasting, and offer better suggestions. A more systematic process can reduce stockouts and overstock, promote greater cash flow health, and improve your customers’ experiences!

Accurate Demand Inventory Forecasting: 10 Considerations

- Historical Sales Data Analysis

Analysis of past sales data is a necessary consideration for trustworthy demand inventory forecasting. The data helps to describe when customers are likely to purchase, discover seasonal and cyclical demand, and identify product life cycles. By exploring what has happened in the past and exceptions and examining those patterns, businesses can develop well-informed forecasts about the potential shifts in demand. By not reviewing the previous forecast, supply chain professionals increase their chances of constructing unrealistic forecasts which leads to inventory inaccuracies.

- Integration of Predictive Demand Planning Tools

Advances in technology have transformed the prospect of demand forecasting. Predictive demand planning solutions can help companies to systematically measure a multitude of variables – past demand, marketing activities, and macros – from which they will receive machine learning algorithms that forecast actual demand. These technologies are useful in that they detect additional patterns of demand that older methods routinely fail to detect. This enables more precise inventory replenishment and significantly reduces the risk of stockout or excess inventory situations.

- Monitoring Market Trends

Market trends have a direct impact on demand for products. The demand can change quickly in reaction to the launches of new products, moves by competitors, or shifts in the economy. To accurately forecast inventory demand, businesses must continually monitor and research market trends. When businesses align their inventory levels with prevailing trends, they eliminate the risk of lost sales due to inventory shortages and expensive overstock.

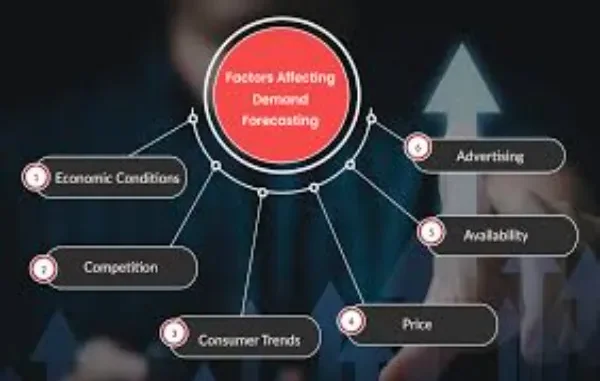

- Incorporation of External Factors

External factors such as the weather, political happenings, and economic policies consistently create sudden alterations in the level of demand for products. Enhanced predictive demand planning systems encompass these external factors to assist with predicting the demand increase or decrease that may not be apparent from the sales history. For example, a cold snap would increase demand for heating products, while a natural disaster could disrupt supply chains and cause purchasing patterns to change.

- Cross-Departmental Collaboration

Planning accuracy improves when departments communicate insights and collaborate on plans. Sales teams inform patients of future sales or contracts; marketing informs product launch dates; finance informs budget constraints; and the supply chain provides lead time and supplier capacity. By sharing the intended outcome and condition of a supply chain inventory demand plan, with market conditions and internal business objectives, companies can better manage their inventory.

- Frequent Forecast Review and Adjustment

Demand estimates must be changed along with the addition of further data. Forecasts should be periodically reviewed and revised to capture the most recent performance and market conditions. Organizations that use predictive demand planning leverage streams of real-time data to allow for actualized projections, reducing estimations, and managing flexibility.

- Product Segmentation

Each product has different demand profiles. Companies can utilize a variety of forecasting techniques by establishing a classification set based on velocity, profit, and seasonality. For example, fast-moving items may require weekly or daily forecasts, while slow-moving items may only need monthly estimates. This more sophisticated hierarchy not only provides greater accuracy in inventory demand forecasting but also provides greater accuracy in inventory turnover.

- Demand Sensing Techniques

Demand sensing leverages real-time data, including point-of-sale transactions, social media trends, and promotions, to identify short-term shifts in demand. When used in combination with predictive demand planning, demand sensing allows companies to respond quickly to evolving signals from the market. This reduces the likelihood of forecast error that can arise from unexpected demand shocks, which increases flexibility when it comes to inventory decision-making.

- Accurate Lead Time Management

Understanding supplier lead times and variance is important when determining the alignment of inventory replenishment to the expected demand. If lead time is overestimated, holding costs will be excessive, while underestimation of lead time could lead to stockouts. Since procurement and supplier lead times are based on dynamic market conditions, if precise lead time information is included in the predictive demand planning models to generate procurement orders, there is improved alignment to demand estimates and reduced holding costs from stock levels.

- Utilizing Big Data and Artificial Intelligence

Big data and artificial intelligence (AI) have transformed inventory demand forecasting. These technologies can analyze large and complex datasets that go beyond human capability. AI-based predictive models are not static—they continuously learn from new data and update their forecasts to improve accuracy over time. This helps businesses make better inventory decisions, respond faster to market changes, and build a more resilient and flexible supply chain.

Bottom Line

Accurate inventory demand forecasting requires strong data analysis, the right technology, and cross-functional teamwork. The 10 key factors discussed—ranging from historical data to AI and demand sensing—help businesses create smarter, more flexible forecasts. By using predictive tools and replenishment optimization software, companies can reduce costs, improve customer satisfaction, and build a more agile and competitive supply chain.

Leave a Reply